Contents

Timothy Thiele holds an associate degree in electronics and is a member of IBEW Local #176. With more than three decades of expertise, he specializes in wiring for residential, commercial, and industrial projects.

Whether you’re replacing a socket, setting up a new lighting fixture, or upgrading your irrigation system, it’s likely that you’ll need to join several wires together properly to ensure your new device or outlet functions correctly.

A simple method for establishing circuit wire connections involves using a small component made of plastic or ceramic known as a wire connector or wire nut. Understanding the appropriate sizes of wire nuts for various projects is essential for ensuring the durability of your DIY wiring and avoiding loose connections.

Wire Connector Sizes by Color

Standard wire connectors are available in five primary sizes, typically identified by color codes that indicate the range of wire gauges, or thicknesses, measured in AWG, suitable for each size. Larger wire connectors are also capable of accommodating wires that handle higher voltages or increased power.

The hues may differ, but typically:

- Gray wire connectors are suitable for wires ranging from 22 to 16 AWG and can handle voltages of up to 300 volts.

- Blue wire connectors are designed to handle wire sizes ranging from 22 to 14 AWG and can support voltages of up to 300 volts.

- Orange wire connectors are suitable for wires ranging from 22 to 14 AWG and can handle voltages as high as 600 volts.

- Yellow wire connectors are suitable for wire sizes ranging from 18 to 12 AWG and can handle voltages of up to 600 volts.

- Red wire connectors are designed to fit wires ranging from 18 to 6 AWG and can handle voltages of up to 600 volts.

You might encounter green wire connectors, designed for connecting copper grounding wires, as well as purple wire connectors, which are suitable for joining aluminum and copper wires.

Tip

Keep in mind that wire gauge is indicated by numbers, with lower numbers corresponding to thicker wires. Consequently, gray wire nuts are designed for the thinnest wires, while red wire nuts are intended for the thicker ones.

Different Varieties of Wire Connectors

Several primary varieties of wire nuts and connectors are available for various electrical wiring tasks both inside and outside your home.

Standard

Twist-on wire connectors, commonly known as wire nuts, are identified by color according to the wire sizes they accommodate. These connectors can come in various shapes, including round, square, or with integrated wings to facilitate manual twisting. Typically crafted from robust plastic, they provide insulation for the wires and are designed to endure the heat produced by standard household electrical connections.

Long Skirt

Deep skirt wire nuts resemble standard wire nuts, but feature an extended skirt or body that accommodates longer sections of exposed wire, offering enhanced insulation and protection for the connection.

Weatherproof

Underground and waterproof wire connectors feature a silicone sealant that safeguards the wires against moisture in outdoor electrical applications. Specifically, underground wire nuts are approved for direct burial.

High-Temperature

High-temperature wire nuts, crafted from ceramic or thermoplastic to resist melting, are utilized in heating systems and lighting fixtures. It’s important to remember that ceramic is significantly more delicate than plastic, so connections should be handled with caution. Pre-twisting the wires is advisable to minimize the risk of applying too much force.

Push-In

Push-in wire connectors have a more streamlined design compared to traditional options, allowing for wires to be inserted into designated clear openings rather than being twisted together. They support a narrower range of wire sizes, generally from 22 to 12 AWG, compared to standard wire nuts.

Unique Bonds

There are also wire connectors that resemble the typical types but are specifically made for unique applications, such as establishing a grounding point during outlet rewiring or connecting aluminum and copper wires in older residences. These connectors are typically colored green and purple, respectively.

Sizes of Wire Nuts for Different Fixtures

Typical wire nuts are suitable for most household wiring tasks, including outlet receptacles, control panels, fans, garage doors, and doorbells. Nevertheless, certain fixtures in the home may necessitate the use of specialized connectors.

For instance, when making connections in light fixtures and heaters, it’s advisable to utilize high-temperature or ceramic wire nuts, while waterproof or underground wire nuts are necessary for outdoor lighting, sprinkler systems, and pool pumps.

If you find yourself uncertain about the requirements of your project, it’s best to consult a professional for assistance.

How to Utilize Wire Connectors

Always adhere to the manufacturer’s guidelines, as they may differ depending on the product. However, the typical process is as follows:

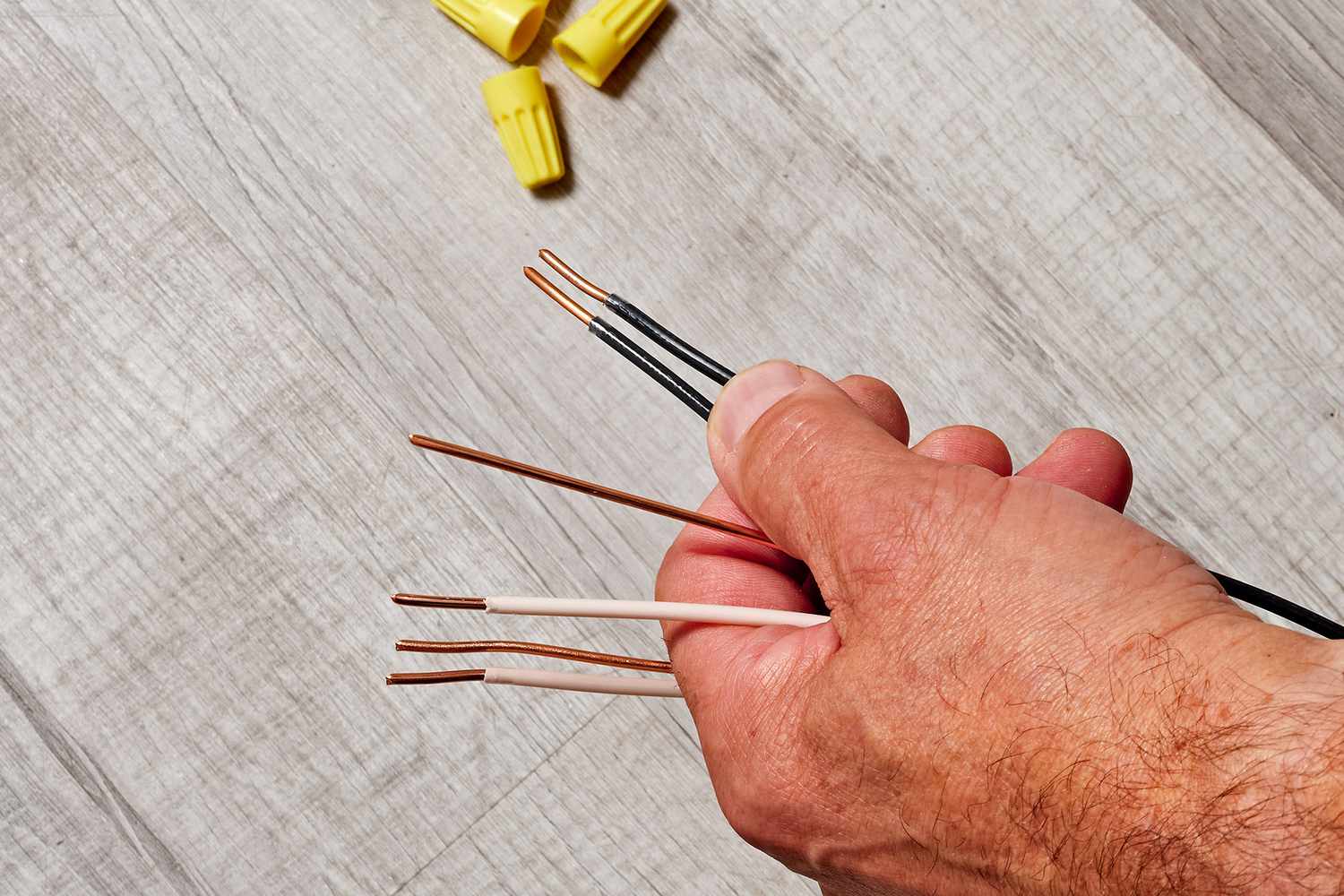

- Remove approximately 1/2 to 3/4 inch of insulation from the tip of each wire using a wire stripper.

- Keep the wires in position, ensuring the ends are properly aligned.

- For added security, you may choose to twist the wires in a clockwise direction using pliers prior to securing them with a wire nut.

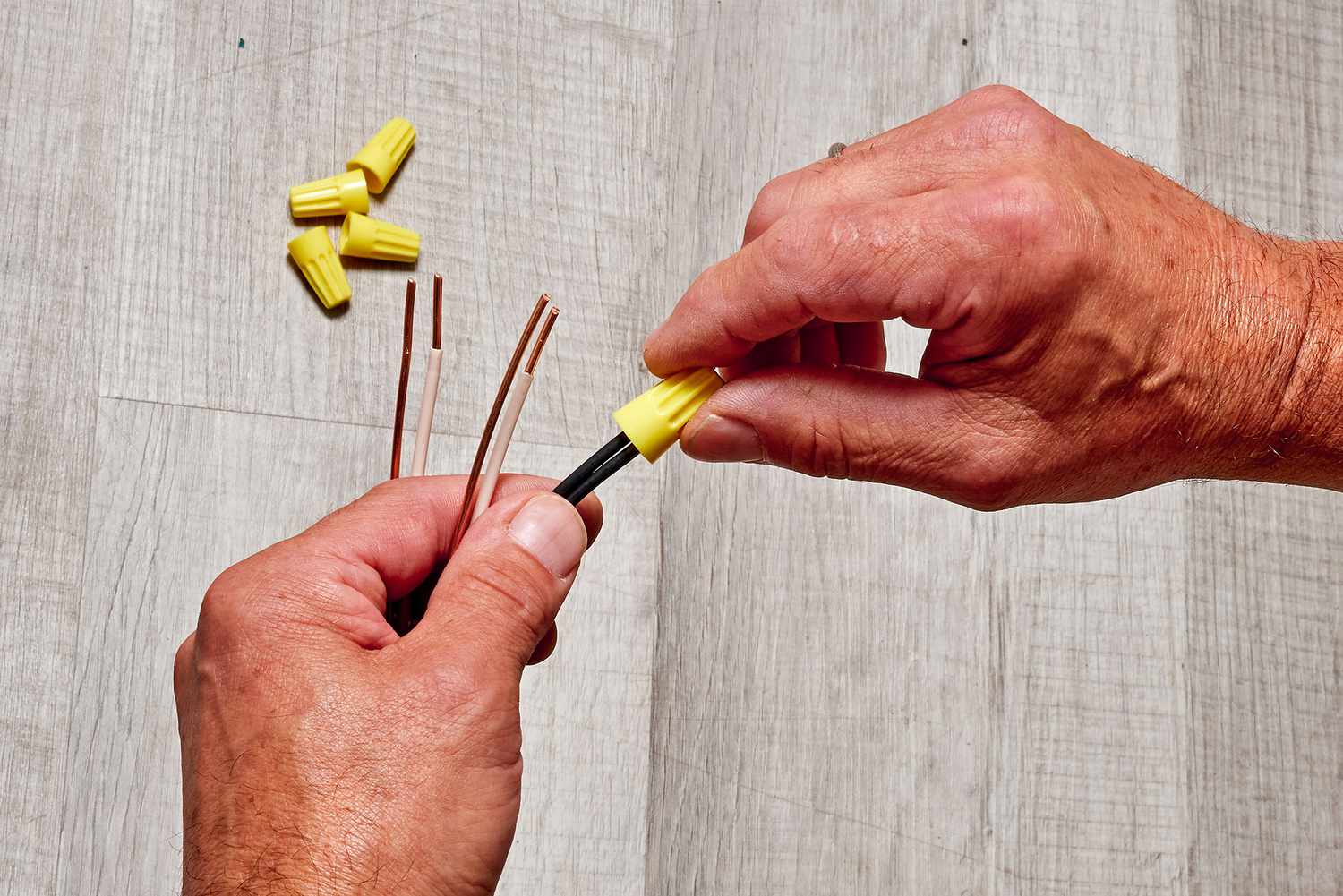

- Choose the correct size of wire connector, position it over the wire ends, and twist the connector clockwise while pushing it onto the wires.

- Secure the nut as firmly as you can, ensuring that no exposed wire is visible. For an extra tight fit, you can also give the nut a brief twist using a pair of lineman’s pliers.

- Gently pull on each wire to ensure it is firmly secured by the nut. If you find any looseness, take it out and begin the process again.

:max_bytes(150000):strip_icc()/what-are-wire-connectors-1152349-04-8b8222ed7d5c4aa39d2d6a065a7ba850.jpg)

Tip

When joining a solid copper wire with a stranded copper wire, make sure to strip the stranded wire an additional 1/8 inch back. Align the wires so that the ends of the insulation meet before proceeding with the remaining steps outlined earlier.

Mold Mitigation and Elimination: Expenses, Procedures, and Additional Information

Mold Mitigation and Elimination: Expenses, Procedures, and Additional Information The Starfish Cactus is the perfect succulent to cultivate this summer—discover the best ways to care for it.

The Starfish Cactus is the perfect succulent to cultivate this summer—discover the best ways to care for it. Step-by-Step Guide Installing String Light Poles in Your Backyard

Step-by-Step Guide Installing String Light Poles in Your Backyard