Contents

Bob Formisano is a certified architect and builder who brings nearly four decades of expertise in constructing new residences and renovating historic properties. He is particularly skilled in restoring outdated systems from the 1920s, such as galvanized plumbing and knob-and-tube electrical wiring. For over a decade, he has been writing articles focused on home repair.

:max_bytes(150000):strip_icc()/repair-washing-machine-water-level-fill-switch-1824607-hero-f7677789212746bdb1be2eaad58be1dc.jpg)

Your washing machine contains several internal switches that manage different operations, and any of these components could fail and need to be replaced. One example is the water level or pressure switch, which may encounter issues due to a blockage in its pressure hose or an electrical fault. You can easily clear the hose through a straightforward process, and a multimeter can be used to check the switch for any failures.

Warning

Prior to starting any repairs on your appliance, it’s essential to identify the manufacturer and model to find the appropriate manual and parts list. Additionally, verify whether your appliance is still under warranty, as many repairs are best handled by skilled professionals. Your warranty might even provide a customer service hotline for free assistance. If your appliance is out of warranty, it’s still wise to consult a professional to prevent any potential expensive damage from DIY repairs.

Function of Water Level Switch

The water level sensor transmits electricity from the timer control to the water inlet valve and the temperature sensor whenever the tub requires filling during a washing cycle. As the tub reaches the desired level, the sensor halts the water supply once the internal water level matches the selected setting for a large, normal, or small load. Subsequently, the sensor instructs the motor to start the agitation process.

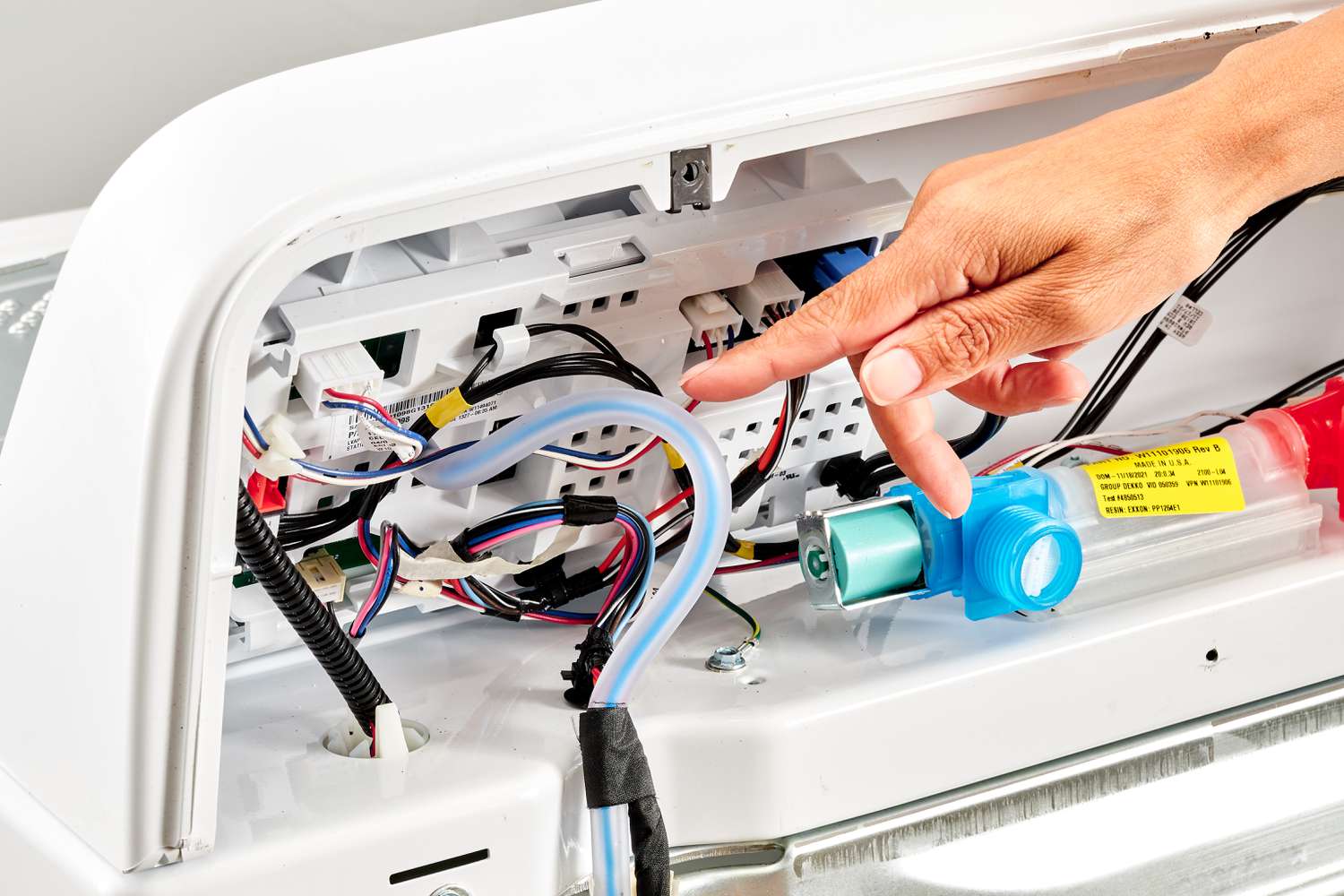

Locating the Water Level Sensor

The location of the water level switch varies across different machines; often, it is located within the control console. However, it is advisable to consult your owner’s manual to determine its specific location.

Warning

Prior to disassembling any section of your washing machine, ensure it is unplugged to cut off the power supply. Additionally, refer to your model’s manual for instructions on how to reach the console, controls, and sensors.

The water level switch can be identified among the other circular switches in the washer’s cabinet by the rubber tube that extends from the switch down the side of the tub. As the washer fills with water, the liquid flows into the tube from the bottom, raising the pressure in the tube’s airspace. Once the pressure hits a certain level, the switch stops the water from flowing into the tub.

Examining the Cylinder

Examine the water level tube and remove any obstructions if needed. Always ensure the machine is disconnected from the power source before performing any checks or maintenance on your washing machine.

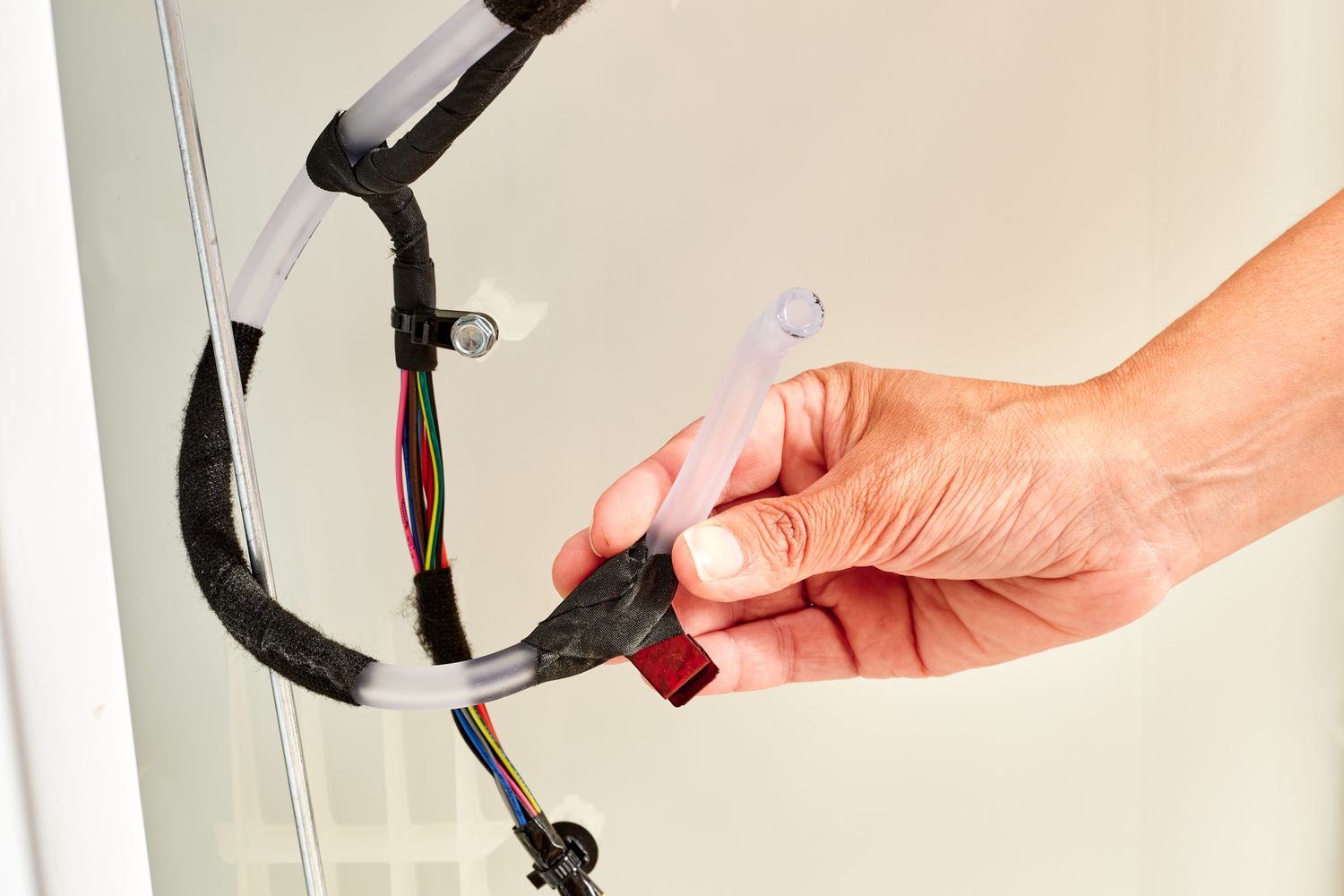

- Locate and examine the tube that extends from the base of the water level switch to the bottom of the tub. It ought to be securely attached to the fittings on both ends.

- Remove the tube from the connectors at both ends. Typically, this requires loosening the clamps to allow the tube to be detached from the fittings.

- Examine both ends of the detached tube for any signs of debris, sediment, or moisture.

- Examine the tube for any bends or punctures. Address any issues by either straightening the tube or replacing it.

- If you notice any buildup inside the tube, make sure to clean it thoroughly. Sometimes, a simple cleaning can resolve issues with a faulty switch, but it’s important to proceed with the next troubleshooting step.

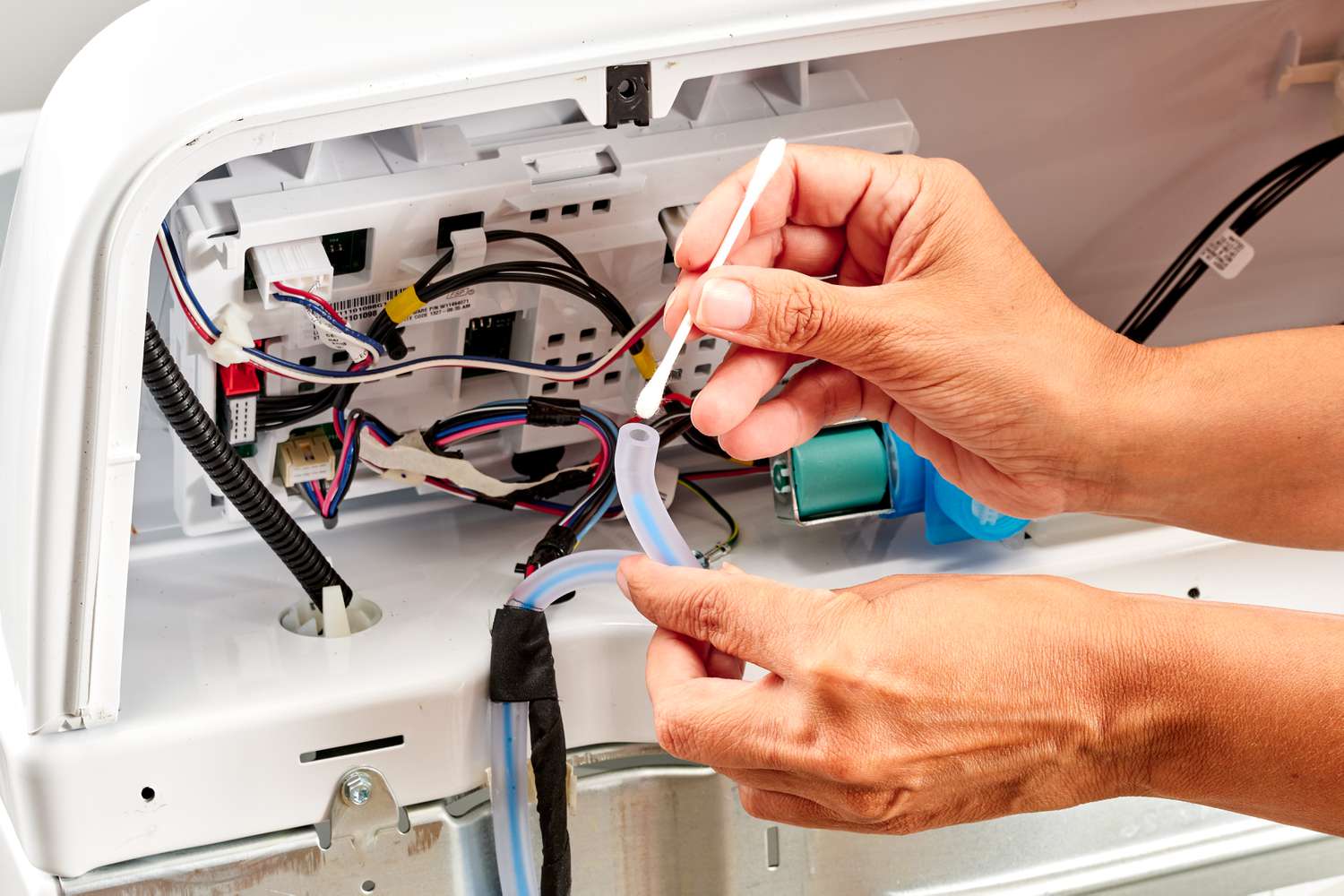

Evaluating the Switch

Next, check the switch for any electrical issues. To assess the switch for continuity, utilize a multimeter, which is also known as a volt-ohm meter, and set it to the OHMS x 1 setting.

- Locate the wires that connect to the switch terminals. Detach them from the terminals: typically, this involves unplugging a wire connector. However, if the wires are attached to the terminals in a different manner, make sure to label them according to their positions before removing them.

- The water level switch is equipped with three terminals. To check for continuity, test the terminals in pairs. Begin by placing the meter probes on terminals 1 and 2. Observe the reading, which should indicate either ∞ (infinity, signifying no continuity) or a value near 0.0 (indicating continuity).

- Connect the probes to terminals 1 and 3, and observe the measurement (∞ or around 0.0).

- Connect the probes to terminals 2 and 3, and observe the measurement.

- Examine the outcomes of the continuity tests: Two of the pairs should show no continuity, while one should indicate continuity. If the results differ from this, the switch is faulty and requires replacement.

- Reconnect the tube to the switch to prepare for the second phase of continuity testing, ensuring that the opposite end of the tube remains unplugged.

- Gently exhale into the tube while rechecking the terminals for continuity in pairs, following the same order as in the initial testing phase. You should hear the switch activate as you blow into the tube. Keep the air pressure steady by pinching the tube shut while testing the terminals, and record your findings.

- Examine the outcomes of the second testing phase and contrast them with the findings from the initial phase. Pairs that lacked continuity during the first phase should demonstrate continuity in the second phase (when pressure is applied in the tube). Conversely, the pair that exhibited continuity in the first phase should not show continuity in the second. Any results that deviate from these expectations indicate that the switch is faulty and requires replacement.

- If the continuity test shows no electrical issues with the switch, reattach the cleaned and straightened pressure tube to the nipple located at the bottom of the tub, and then operate the machine through a cycle to check if the issue has been resolved.

25 Enclosed Patio Ideas to Make Your Outdoor Space Cozy

25 Enclosed Patio Ideas to Make Your Outdoor Space Cozy Steps for Cleaning an Electric Kettle

Steps for Cleaning an Electric Kettle 2023 Ultimate Patio Umbrella Buying Guide Find Your Perfect Shade

2023 Ultimate Patio Umbrella Buying Guide Find Your Perfect Shade